We provide technically skilled and specialized solutions for all issues related to your hydraulic machines/systems/installations/equipment, such as:

Solution for safe maintenance

Solution for safe maintenance

We ensure the flawless and safe operation of your systems.

Our service area for maintenance, repairs, and commissioning extends from our headquarters in Nuremberg to worldwide locations. For more information and inquiries, please contact

our hydraulic specialistsModification and expansion

In addition to maintaining existing systems, we also offer modifications and upgrades to make your systems even more efficient, safe, and reliable.

System and Unit Construction

We also offer the construction of systems and units tailored to your specific needs. Additionally, we leverage our experience and expertise to fine-tune the control and regulation technology of your systems, ensuring efficiency and longevity of your machinery.

Assembly and Commissioning

Furthermore, we install new or additional systems and commission them together with you. Our top priority is a smooth commissioning process, along with continuous advice and support.

Components and Accessories

To this end, we provide high-quality and specialized machinery and individual parts, ranging from pumps and motors to valves, cylinders, and other accessories. In particular, we maintain a comprehensive inventory of valves and pumps and offer an exchange program for timely and suitable replacement of wear parts. Your hydraulic systems can be manufactured according to your specific specifications, dimensions, or requirements.

Components from In-House Production

To guarantee the best possible components, we are not tied to any single manufacturer. We either find a suitable product for you or manufacture it ourselves. If you have further questions about maintaining your systems, please contact

our hydraulic specialistsMeasurement Connection: serv-Clip & Flow Sensor: fluid-Check

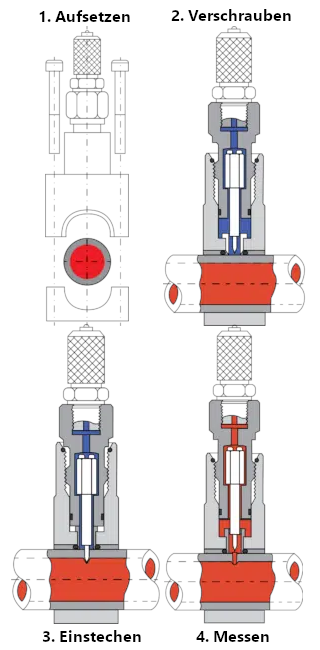

Easy Installation of the serv-Clip

Easy Installation of the serv-Clip

Here’s how to protect your system from daage caused by insufficient lubrication or contamination in hydraulic or gearbox oil.

Example of Low Lubrication Oil:

The fluid-Check® flow sensor detects insufficient oil flow while pressure gauges and switches might still be within the normal range. By detecting this "issue" early, repairs and maintenance can be initiated in time, preventing more significant damage to the system.

Fluid-Check diagnostic system - the solution for:

For more information, please contact

our hydraulics specialist